Consultancy Design

DEHUM provides a comprehensive consultancy and design service, specializing in the delivery of complete, turnkey solutions tailored to diverse applications.

With a strong focus on innovation and precision, DEHUM excels in developing bespoke systems designed to address complex challenges and niche requirements. The company follows the RIBA Plan of Work design stages — from initial preparation and concept design through to technical development, construction, and handover — ensuring a structured, transparent, and client-focused approach throughout the project lifecycle.

Committed to engineering excellence, DEHUM continuously adopts the latest advancements in design technology, ensuring each solution meets the highest standards of performance, efficiency, and long-term reliability.

What is Consultancy Design

As experts in environmental and humidity control, DEHUM recognizes that complex projects demand a structured, methodical approach. To achieve this, we integrate the RIBA Plan of Work into our consultation projects, ensuring clarity, precision, and efficiency throughout the process. We utilize advanced SolidWorks 3D CAD software to create detailed models and drawings, enhancing the design visualization and ensuring complete accuracy from concept to completion.

The RIBA Plan of Work outlines eight key stages of a project’s lifecycle, providing a structured framework to guide the design, development, and delivery of projects. For DEHUM’s specialized engineering services — particularly in humidity control, environmental management, and bespoke system design — these stages can be tailored to ensure a seamless, efficient, and results-driven process. Let’s break it down:

The Consultancy Design Process

Crafting our 3D models takes a lot of research. That’s why it goes hand in hand with our site surveys, which involve assessing the application and collecting a lot of data so that the system we design does what you need it to.

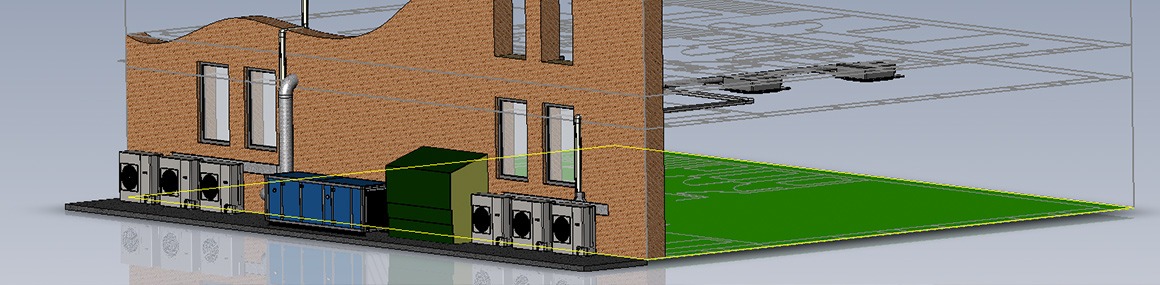

Our design software package also allows us to import the clients’ existing CAD and DWG files which can then be incorporated into our 3D models and layouts. This is a huge bonus for us, as we can show clients exactly how their new system will fit into the application. Showing them a perfect scale model of their factory, warehouse, or building makes our presentations much clearer.

Here’s an example of the type of model we create:

Stage 0: Strategic Definition

Objective: Establish the project’s strategic vision and assess feasibility, aligning with the client’s overarching operational and environmental goals.

DEHUM’s Approach:

- Facilitate in-depth consultations to capture environmental control challenges and performance expectations.

- Define key performance indicators (KPIs) such as humidity regulation, energy efficiency, and sustainability objectives.

- Conduct a high-level infrastructure assessment to outline strategic solutions and potential pathways.

________________________________________

Stage 1: Preparation and Brief

Objective: Develop a comprehensive project brief that defines the scope, objectives, and performance outcomes.

DEHUM’s Approach:

- Execute detailed site surveys to acquire critical data on environmental conditions, spatial constraints, and existing system performance.

- Collaborate with stakeholders to ensure project goals, success criteria, and long-term performance benchmarks are meticulously defined.

- Establish a preliminary timeline, resource allocation, and project roadmap.

________________________________________

Stage 2: Concept Design

Objective: Formulate an outline design that incorporates client requirements, operational constraints, and performance objectives.

DEHUM’s Approach:

- Develop initial 3D concept models using advanced SolidWorks CAD software to present clear, immersive visualizations of proposed solutions.

- Explore multiple system configurations to ensure an optimal balance between performance, cost-efficiency, and sustainability.

- Deliver early-stage performance analysis, including airflow modelling and moisture control simulations, to validate design viability.

________________________________________

Stage 3: Spatial Coordination

Objective: Refine the design with an emphasis on seamless integration, coordination, and spatial efficiency.

DEHUM’s Approach:

- Produce comprehensive 3D general arrangement drawings and system layouts through SolidWorks CAD, ensuring precision in spatial representation.

- Ensure full interoperability with existing infrastructure and engage in cross-discipline coordination with other site contractors.

- Optimize system configurations to enhance accessibility, maintenance, and operational performance.

________________________________________

Stage 4: Technical Design

Objective: Finalize a technically advanced, fully detailed design ready for manufacturing and system implementation.

DEHUM’s Approach:

- Generate precision-driven manufacturing drawings, assembly instructions, and system specifications using SolidWorks 3D CAD modelling.

- Define and finalize automation sequences and control system architecture to ensure seamless integration and operation.

- Deliver energy efficiency assessments, ensuring full compliance with industry regulations and environmental standards.

________________________________________

Stage 5: Manufacturing and Construction

Objective: Oversee the manufacturing and installation phases to ensure adherence to design specifications and project timelines.

DEHUM’s Approach:

- Partner with trusted manufacturing suppliers to ensure all components meet specification and quality standards.

- Implement an installation schedule that prioritizes minimal disruption to client operations.

- Verify all system installations adhere to design documentation, performance criteria, and safety standards.

________________________________________

Stage 6: Handover and Close Out

Objective: Ensure systems are fully operational, validated, and primed for long-term performance.

DEHUM’s Approach:

- Conduct comprehensive testing, commissioning, and performance verification.

- Provide tailored training sessions for client teams, ensuring effective system operation and maintenance.

- Deliver thorough handover documentation, including user manuals, performance reports, and maintenance schedules.

________________________________________

Stage 7: In Use

Objective: Ensure sustained system performance and operational longevity through ongoing support.

DEHUM’s Approach:

- Offer proactive maintenance packages and continuous performance monitoring services.

- Provide remote technical support and periodic on-site assessments to maintain system reliability.

- Recommend upgrades or adjustments to accommodate evolving operational demands and environmental regulations.

________________________________________

Driving Innovation, Delivering Results

By integrating DEHUM’s bespoke engineering services with the RIBA Plan of Work — enhanced through SolidWorks 3D CAD technology — our clients benefit from a streamlined, organized, and highly visual design journey. This ensures the delivery of state-of-the-art environmental control systems that consistently deliver operational excellence, long-term reliability, and energy-efficient performance.

The Best Consultancy Design Solutions

At DEHUM, we prioritize building lasting, collaborative relationships with our clients. While our advanced environmental and humidity control systems are designed to deliver exceptional performance, what truly sets us apart is our unwavering commitment to understanding and solving our clients’ unique challenges.

Many of our clients approach us with highly specialized, humidity-related issues that require more than off-the-shelf solutions. Whether operating within niche industries or managing bespoke processes, these businesses rely on DEHUM’s expertise to develop tailored, high-performance systems.

Our consultancy design process is integral to this success. By leveraging advanced SolidWorks 3D CAD technology, we create detailed, accurate visualizations that offer clients a clear understanding of the proposed solution. This approach not only enhances transparency but ensures alignment before any physical production begins — streamlining the path from concept to implementation.

At DEHUM, we don’t just provide systems — we deliver precision-engineered, client-centric solutions designed to perform flawlessly in even the most demanding environments.