Humidity Control in Lithium Battery Manufacturing

August 5, 2024

Lithium batteries have been one of the most important inventions of the last century. Since their initial creation in 1976, they’ve become a staple of technology and innovation, powering everything from phones and electric cars to medical implants.

With so many vital uses, the production of lithium batteries has become a huge industry. Lithium-ion batteries aren’t something we can put together in our garden sheds; in order to be made safely, and maintain the high-quality customers expect, you need the perfect conditions.

To achieve these perfect conditions, you need to control humidity. Today we’re going to explain why lithium-ion battery production needs quality humidity control, and also explain why these batteries are so important.

The Importance of Lithium-Ion Batteries

We’ve already mentioned the widespread use of lithium-ion batteries, but why are they the go-to? Well, the clue is in the name.

Lithium is a lightweight metal that possesses a high electrochemical potential, essentially meaning it can store more energy than other elements. There is some controversy regarding lithium mining, but there’s no denying that it’s the best material for the job in terms of efficiency and affordability.

Lithium-ion batteries have incredibly long life cycles compared to batteries containing lead and nickel (which were the most common in the past) and require zero maintenance once installed.

However, creating and installing lithium batteries is a tricky job, and one that needs to be done in the perfect conditions.

Conditions Required for Lithium Battery Production

When assembling or installing lithium batteries, you need a ‘dry’ room. These are similar to clean rooms; lab conditions with no airborne particles or pollutants that can damage vulnerable parts  and materials. However, most clean rooms have a relative humidity of 40-60% percent and levels are allowed to fluctuate naturally within this range. Dry rooms, on the other hand, need a strict relative humidity of less than 5%.

and materials. However, most clean rooms have a relative humidity of 40-60% percent and levels are allowed to fluctuate naturally within this range. Dry rooms, on the other hand, need a strict relative humidity of less than 5%.

The reason for this is that lithium can deteriorate quickly in humid air. If any moisture comes into contact with lithium, it will produce lithium hydroxide, hydrogen, and heat. This exposure to moisture directly impacts the quality, performance, and shelf life of the batteries you produce.

By keeping it below the 5% threshold, your team has enough time to install and assemble electronics or batteries before the lithium degrades.

Keeping the humidity this low isn’t possible with an off-the-shelf dehumidifier. Don’t worry, that’s where we come in.

Controlling Humidity during Lithium Battery Production

Dry rooms are large installations within a plant, lab, or factory. This means that the dehumidification systems are built into the dry room or adapted to suit your needs.

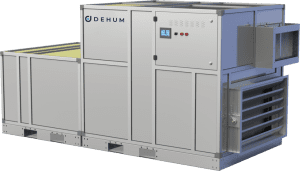

Our industrial dehumidifiers guarantee that you’ll have the optimal conditions for creating lithium-ion batteries. They work alongside associated heating and cooling systems, controlling the air quality and, of course, reducing the humidity down to the ideal levels.

For dry rooms we recommend desiccant dehumidifiers. These are more compact than our other systems, without sacrificing efficiency. This means that you will have more space to work with, and they use less energy as an added bonus.

All of our industrial dehumidifiers are designed to be as economical as possible. After decades of R&D, we’ve developed systems that shut themselves down automatically to save power, switching themselves back on when they detect humidity levels rising. They can also adapt automatically to changing temperatures, meaning they’ll work perfectly no matter the climate, season, weather, or time of day.

If you do need to adjust our systems, we make it easy to do so. With clear displays and simple controls, you can adapt every element of your industrial dehumidifiers with minimal training and instruction. Depending on what you are producing, your team may need to adapt the air quality, temperature, or humidity quickly to keep conditions correct. With our systems, it’s a breeze.

Manufacturing Lithium Batteries Safely

When working with fragile or volatile compounds, safety is paramount. Your team are experts when it comes to working with lithium, but if the conditions aren’t correct, they could be in danger.

Our systems aren’t just about improving your output, we use our knowledge and experience to ensure the safety of your production line, and the people running it.

Our systems aren’t just about improving your output, we use our knowledge and experience to ensure the safety of your production line, and the people running it.

With years of knowledge and decades of providing the best dehumidifiers, we understand the legislation involved almost as well as you do. Our humidity control systems are innovative, but still comply to all legal requirements, giving you peace of mind.

If more of your products pass quality control, it will directly affect your bottom line. Pair this with an increase in efficiency, and overnight you can become a powerhouse in the battery production world. As you’re using valuable components, inconsistent quality can be very expensive as full batches will be inferior at best or may even require disposal. There are a lot of people keeping a close eye on the world of lithium battery production; choosing quantity over quality will ruin your reputation.

Why Choose Dehum for Lithium Battery Production?

Manufacturing lithium-ion batteries is a huge business, and one that can be very lucrative for a company wishing to expand its output. However, these batteries are complicated to produce, and risky if you don’t have the right systems in place.

Unlike other dehumidifier providers, we meet with you to establish your exact needs, assess your space, and discuss what humidity control systems would suit your business. We then design bespoke systems that fit your requirements and guarantee an improvement in productivity from the moment they are switched on.

With our customised dehumidifiers you don’t need to spend time adapting your facilities to suit an off-the-shelf solution that works, but not as well as it could. For our more advanced industrial dehumidifiers, we even provide training for you and your staff.

After two decades of working with lithium battery manufacturers, we know what works best, and have given our existing clients the edge they need to succeed, surpassing rivals and gaining a foothold in one of the most competitive industries.

We’ve also been behind some truly exciting and innovative new technologies, which have virtually eliminated many of the issues that uncontrolled humidity can cause.

If you need help with humidity control or have any questions about us and what we do, please email us on sales@dehum.com or call 01926 882624.

We look forward to hearing from you.

![]()