Applications of a Commercial Dehumidifier and How they Work

May 18, 2020

Since being invented in 1955, commercial desiccant dehumidifier systems have come a long way in solving humidity problems across many industries.

On the surface, the impacts of humidity may not seem obvious. However, you may be surprised that the UK has one of the highest relative humidities (RH) globally, at 80% RH. The RH is determined by the volume of water in the air, so the higher the percentage, the higher the humidity.

High-level humidity can cause a range of problems that, once the damage is done, can be costly to solve, cause unnecessary downtime in production and even do unmendable damage. So it’s in the interest of many industries to explore possible solutions, especially here in the UK, where the atmosphere is against many materials and components.

Read ahead to find out how commercial dehumidifier systems have transformed quality control within various sectors and why they are the answer to getting your humidity levels under control.

What problems does humidity cause?

Corrosion: corrosion is the conversion of refined metal (including the metals that make up cars and machinery) into a more chemically stable metal. The material reacts to moisture and air, which causes rusting. For steel, corrosion starts at just 40% RH and climbs rapidly above this- with the average humidity in the UK being 80%; this causes corrosion day in and day out.

Mould and hygiene problems: A high humidity can provide the perfect breeding ground for bacteria and mould. This can cause significant issues if you’re in a sector such as food manufacturing, where a sterile environment is essential for consumer health and safety. To avoid the growth of mould and the spread of infectious bacteria, the RH needs to be kept between 30-50%.

Damage to machinery: In some manufacturing environments, steam is an inevitable by-product. Breweries, for example, produce a humid micro-climate resulting from the temperature fluctuations from hot to cold during different processes. If lots of water is consistently deposited onto surfaces, machinery, or even the pipework connecting it is more vulnerable to damage.

Quality control: In many sectors, such as the pharmaceutical industry, humidity levels must be controlled. This is because measurements are required to be extremely precise, and the quality control of the drugs needs to be executed to the highest degree to protect public health. High humidity can cause the product to absorb moisture, degrading its quality. To protect the product, RH levels are required to be around 50%.

What is the traditional solution for these problems?

There are various solutions out there to choose from. The two most commonly used (aside from dehumidification) are heating and ventilation.

Heating is used in an attempt to combat the relative humidity- a figure that indicates how saturated the air is with moisture. Increasing temperature means the air can hold more moisture, so the relative humidity is lower. Adversely, a low-temperature scenario will result in much more condensation; this is why the winter months are often a time of concern around sensitive materials in unconditioned environments.

Because of this, some opt for a heating solution that maintains a high enough temperature to reduce the likelihood of condensation.

However, this solution is not energy efficient, cheap to run or environmentally sustainable. Additionally, if there’s a lack of insulation in the space it’s heating, the heat will escape.

Ventilation is used as another method to try and combat the effects of humidity. A method like this aims to increase airflow over products and materials.

Like you would blow on a hot drink to help it cool down, airflow keeps moisture-laden air moving around materials without settling and condensing.

The issue with a solution like ventilation is that it’s inconsistent, uncontrolled and unconditioned. On a still day, having a ventilated room would make virtually no difference to the airflow, and even on a day where the atmosphere will be well-circulated, the air that is being ventilated will have the same moisture content as the air within the space it’s entering.

Heating and ventilation are both attempts to combat the effects of relative humidity. It won’t do anything to alter the relative humidity levels or moisture content within the air, so calling them solutions to the problems of humidity is somewhat of a stretch. They have the disadvantage of being difficult to control and expensive to manage.

Heating, cooling and ventilation are great for human comfort, but where we feel the effects of heat, materials don’t. They are affected by humidity more than anything else, so a solution that caters towards that fact will by far be more effective.

The most effective way to combat humidity is to have a solution that tackles humidity rather than attempting to balance different conditions on a knife edge for preventing condensation.

The right solution (commercial dehumidifier)

A commercial dehumidifier is a perfect solution to use across a variety of industries which require humidity control.

It tackles humidity at its source by removing moisture from the environment to get it to achieve your ideal RH. By getting a commercial dehumidifier made, tailored to your specifications, you will have an energy-efficient, cost-effective and lasting solution to all of your humidity problems.

By removing moisture from the atmosphere, you can have your space at whichever temperature suits you, as there is no moisture to worry about condensation from.

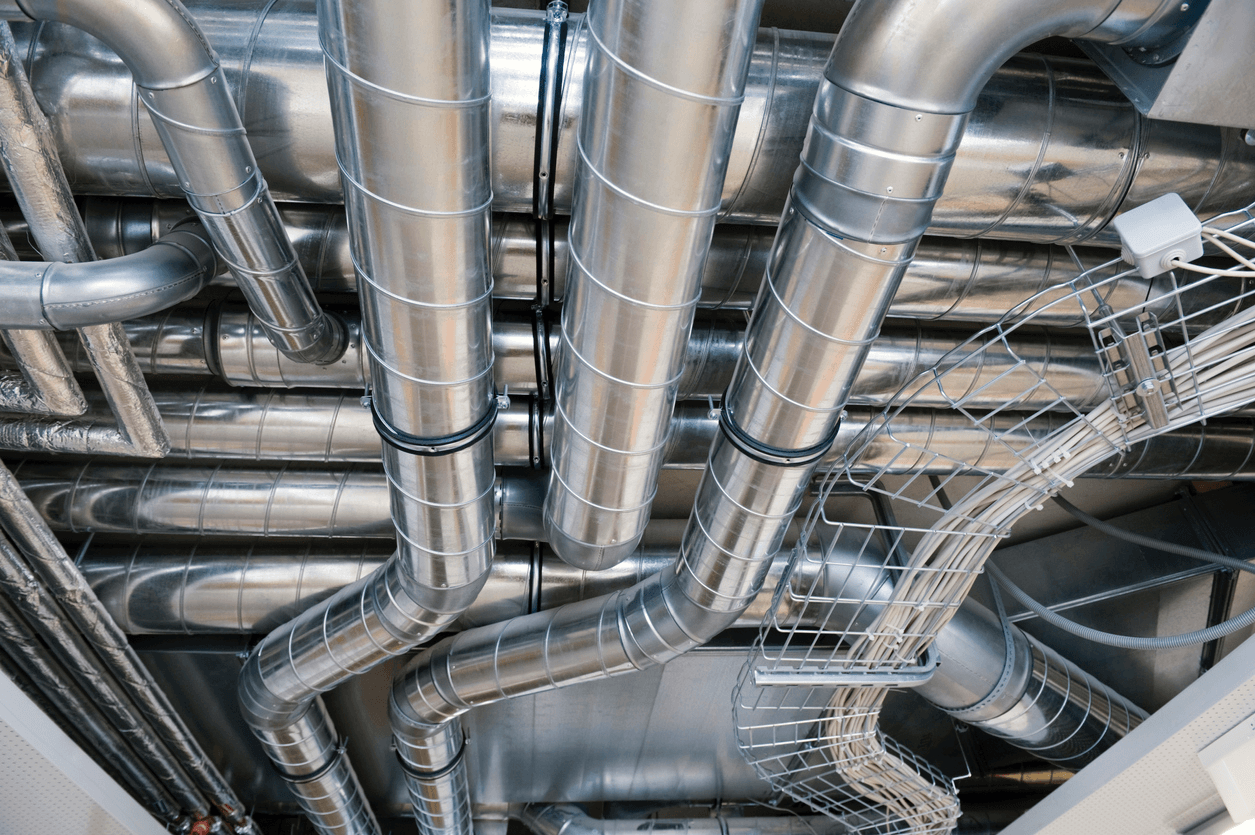

Dehumidification also removes the necessity for ventilation. Our dehumidifying systems are laid out in a series of ductwork that will maintain airflow wherever required by blowing the dry, conditioned air to the areas that need it.

Our dehumidifying systems can be used in an array of unit sizes and across various industries.

How does it work?

The desired RH level is input into the commercial dehumidifier’s advanced control system. Air is then passed through the unit, removing moisture. The RH is monitored by the control system so that when it reaches the ideal humidity, it automatically shuts off.

When the environment approaches a pre-set RH, the unit starts up again, repeating the process so that your environment is never in breach of appropriate RH levels and won’t use up unnecessary power by running constantly.

The control system can be managed from a simple PLC controller, ensuring ease of use and environmental conditions can be correctly controlled.

Additionally, the system runs quietly, minimising any noise disruption to workers within the space.

What are the applications?

Commercial dehumidifier systems are used widely throughout several industries, and their applications are relatively unrestricted when controlling humidity levels.

Total control over the ambient conditions in any environment allows you to make better products, faster workflows and more accurate results.

The reason that desiccant dehumidification is useful in so many industries is due to these fine margins in combination with the issues that moisture causes on a more basic level.

The effects of ambient conditions are something that companies across many industries are used to paying for, and they haven’t considered the amount that could be saved by eliminating the effects of humidity.

Some of the industry applications include:

- Pharmaceutical production

- Food and drink industry processing

- Cold stores/ freezer facilities

- Waterworks and utilities

- Lithium battery manufacturing

- Nuclear

- Automotive

- Aviation

- Chemical processing

- Car storage

- Archives

- Wind farms

- General humidity management across a range of indoor spaces

These are just some examples. Essentially, a commercial dehumidifier is an effective solution for almost any space that requires humidity control.

Conclusion

Overall, it’s clear that a commercial dehumidifier solution is the best option when measured up to less impactful- and more expensive- heating or ventilation solutions. The benefits quickly stack up when you consider the intersection of cost-optimisation and the level of impact this solution has.

Without a commercial dehumidifier, you could find yourself in a situation where production time is longer than it needs to be, and costly interruptions to manufacturing may be a result of a lack of effective humidity control. In a world where many industries are becoming more and more saturated, these are the types of areas where eliminating interruptions can cement your place at the top of your industry.

Commercial dehumidifiers present an opportunity to successfully and consistently control RH levels without interruption, giving you more time to focus on what matters: expanding and innovating your business.

For over twenty-five years, DEHUM has been a major supplier of humidity control systems. We are a true Engineering Company, designing, supplying and coordinating equipment installations alongside complimentary services. Our global client list spans all industries, including food & drink, pharmaceutical, nuclear, automotive, aviation, chemical processing, ice prevention/cold storage, car storage and archives.