Condensation on Chilled Drinks Bottles

May 18, 2020

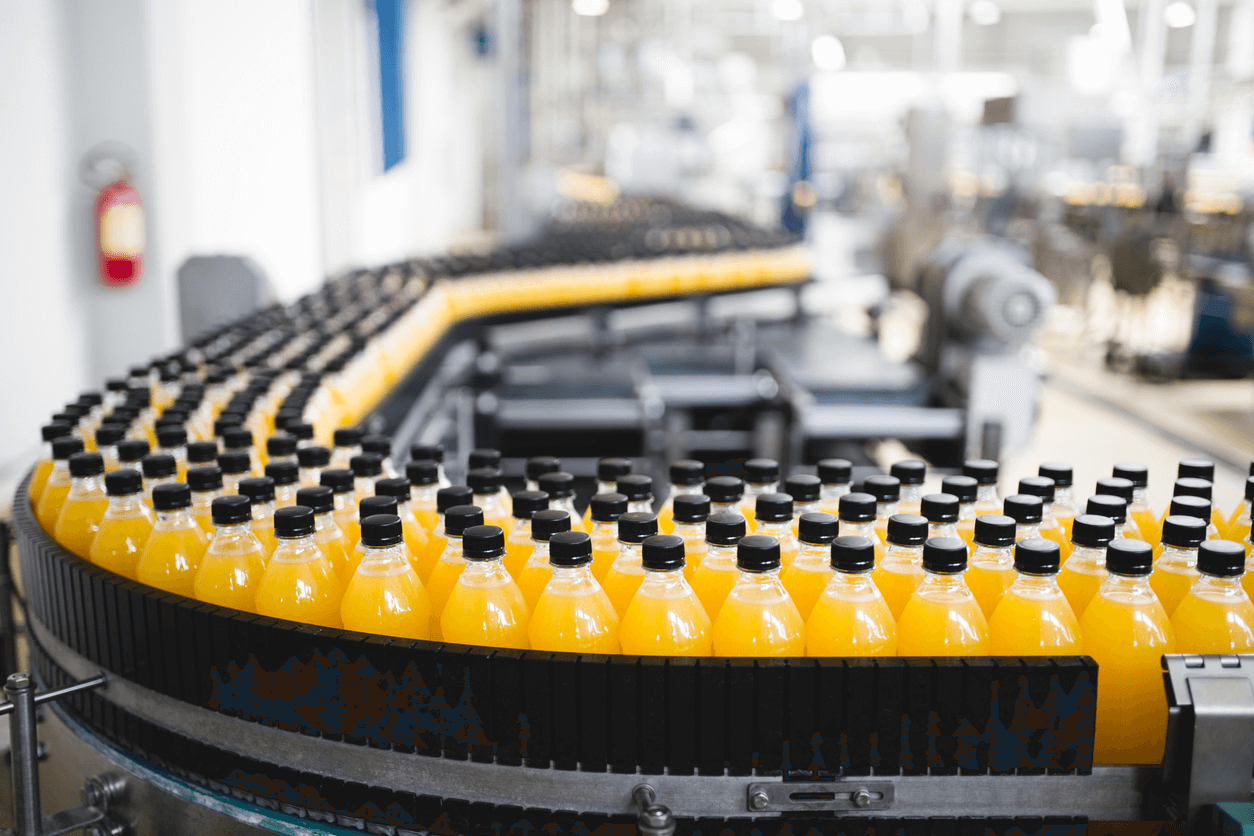

Most people can claim to enjoy the occasional soft drink from chilled drinks bottles. After all, it’s a product that is deeply embedded in our culture and the market only continues to expand with new health drinks as well as the continuing sales of classic favourites, such as Coca-Cola and Pepsi. But how much often do we stop and think about how those chilled drinks bottles get from the factory into our hands and the processes in between?

In truth, our chilled drinks bottles go through quite the journey to deliver the quality of the product that we expect, and tightly controlling the production conditions is central to a smooth and seamless end product.

How are soft drinks made?

The production of soft drinks can be grouped into five general stages:

- Clarifying the water

In this stage, impurities are eliminated from the water, and the desired pH level is met.

- Filtering, sterilising and dechlorinating the water

The water is filtered to remove particles, and the storage tank is sterilised with chlorine. Then an activated carbon filter dechlorinates the water and removes any residual organic matter.

- Mixing ingredients

The sugar and flavours are placed into batch tanks and carefully mixed to make the syrup, avoiding aeration. The syrup may be further sterilised by rapidly heating and cooling the formula. The syrup and water are then combined and pressurised with CO2 to prevent aeration from occurring.

- Carbonating the drink

For carbonation, temperature control is key because lower temperatures cause an increase in CO2 solubility. All beverages are overpressured to mitigate carbon dissolving during movement into storage tanks and filler machines.

- Filling and packaging

The chilled drink bottles are filled with the drink and are immediately sealed. The drinks must be cooled to room temperature before labelling to prevent condensation from damaging the labels. Once packed, they can be shipped to distributors.

Each stage requires rigid precision in measuring ingredients and the processes that combine them alongside highly controlled environmental conditions to ensure that consumer health and safety standards are met.

Why does RH matter?

Humidity has the potential to cause numerous issues in the chilled drinks bottles process.

The UK has one of the highest relative humidities (RH) in the world, with an average of 80% RH year-round. Any controlled environment or microclimate needs a solution to ensure controls can be managed consistently and effectively.

But what are the controls and processes that humidity can disrupt?

- Sugar

The National Soft Drink Association and other agencies set strict standards to regulate the quality of ingredients, including sugar. For example, low-quality sugar contains particles that can spoil the drink. As part of preventing spoilage, the sugar has to be managed in dry, sterile environments.

If the quality of sugar is reliant on a dry environment, a high RH will damage the sugar’s integrity. Not only that, but humidity can provide warm, wet conditions in which bacteria can flourish, accelerated by the sugar.

If this occurs, the quality of the overall product is ruined and is also a potential health hazard that can’t be distributed to consumers.

- Sterile environment

As mentioned previously, a humid environment provides bacteria with the conditions to thrive. However, this doesn’t mean that any level of moisture is bad news.

Research shows that a 50% RH increases the decay rate of bacteria. This resulted in the hypothesis that 40-50% RH could protect against microbial infections. This indicates that the appropriate solution does not remove all humidity but one that can tightly control and adjust the RH of an environment as needed.

The study also suggests that controlling the humidity levels can safeguard against the spread of infection between staff, meaning less production time is lost through staff sickness.

Additionally, a sterile environment reduces the need for preservatives in soft drinks, which is a big selling point in the current health-conscious market.

- Production time

Many internal and external factors pose a risk of impacting the length of production time. But could control the RH provides an opportunity to speed it up?

As mentioned, bottles cannot typically be labelled before they have room temperature to avoid condensation on the chilled drinks bottles that can ruin the label. If you were to lower the humidity, you could label the bottles before waiting for them to cool, as there wouldn’t be any water vapour to condense on the bottle,

While the previous example presents an opportunity, this second one highlights risk.

A high RH will result in water vapour condensing on the factory machines. If this continually builds up and happens in places that are hard to reach and clean, expensive machinery will be vulnerable to damage. This could result in downtime of production as well as the cost of fixing or replacing damaged equipment.

What’s the best solution?

Ultimately, the right solution needs to be one that can not only reduce humidity but can keep it at its optimum level.

The need for other solutions, such as deep cleans to tackle problems like sanitation, will be reduced, as the controls will maintain a consistent environment where things like mould won’t survive.

The answer is a bespoke desiccant dehumidification system created to meet your requirements. They can control the environment of even large spaces with precision and efficiency.

The product has advanced control systems to sense and control airflows. You can also use it to maintain your ideal temperature of the environment, helping you keep conditions sterile.

Conclusion

The global soft drink industry continues to grow with momentum, showing no sign of letting up. With market saturation, companies need to do all they can to remain competitive by ensuring efficiency is at its highest, production times are relatively low, the cost is optimised, and quality and health and safety are always at the top of the agenda.

As standards rise in conjunction with the capabilities of technological solutions, it’s time to invest in a solution that gives you the control you need to deliver top-quality chilled drink bottles to the market.

A dehumidification system provides the assurance of health and safety while also offering a cost-effective and energy-efficient solution.

For over twenty-two years, Dehum has been a major supplier of humidity control systems. We are a true Engineering Company, designing, supplying and coordinating equipment installations alongside complimentary services. Our global client list spans all industries, including food & drink, pharmaceutical, nuclear, automotive, aviation, chemical processing, ice prevention/cold storage, car storage and archives.