Why Bioprinting needs dehumidification

May 18, 2020

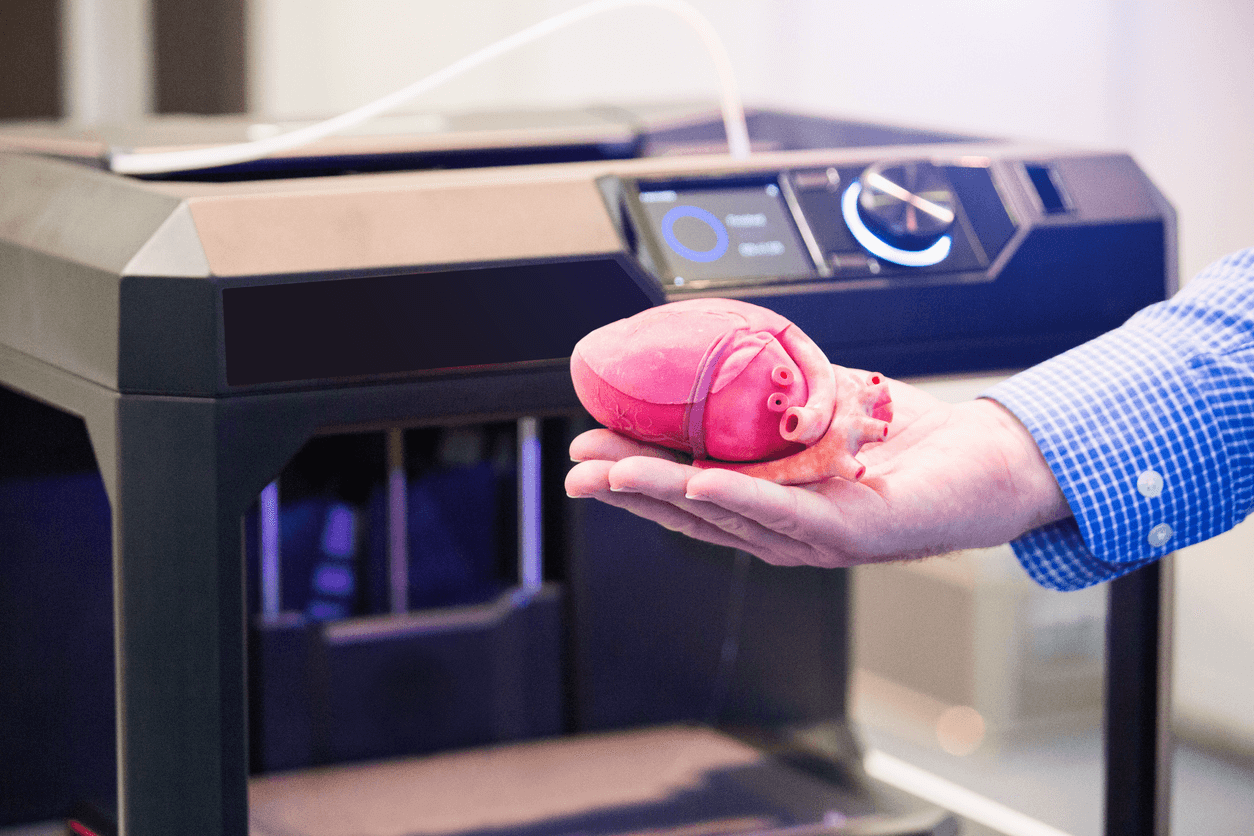

Bioprinting is very much what the future of medicine will look like, with new developments in technology elevating practical capabilities within the field. As we make leaps in technological advancements, the applications of our technology become all the more intricate and impressive.

Bioprinters are no exception. Comparable to conventional 3D printing, they work by ‘printing’ out a physical object based on a digital model. Similarly, 3D printers themselves are also widely applicable to the field of medicine. For example, university teams are working on creating 3D printed ventilators to combat the Covid-19 crisis.

Unlike 3D printers though, bioprinters create organic matter which has a variety of applications, some of which include printing the following:

- Bone grafts

- Simple organs

- Regenerative skin and tissue

- Blood vessels

- Ears

- Exoskeletons

- Windpipes

- Tissue on a chip

But while the technology may seem very new, it’s something that’s been decades in the making- the very first 3D printer was created in 1984 and the discovery of stem cells happened in 1978, making the technology applications we have today possible.

What is Bioprinting?

To understand why dehumidification is essential for Bioprinting, you need to understand what it is and how the process works:

“Bioprinting is an additive manufacturing process where biomaterials such as hydrogels or other polymers are combined with cells and growth factors, then printed to create tissue-like structures that imitate natural tissues.”

The level of detail that goes into creating tissue is high, so accompanying conditions need to be highly controlled.

How does it work?

The process is incredibly intricate and requires the utmost precision. ‘Bioink’ is used for the printing material, and it creates the organic structure layer by layer. Instead of the thermoplastic or resin used by standard 3D printers, a living cell suspension is present in the bioink.

The process is broken down into four stages:

- Preparation- designing the digital plan

- Printing- executing the print

- Maturation- tissue may need incubation

- Application- medical application for patient

The material is highly vulnerable to the impacts of cross-contamination. Because the finished ‘products’ are used in clinical transplantation, a completely sterile environment is an absolute necessity for safety and to eliminate the risk of infection. But what problems can compromise a sterile environment?

The problem with humidity and Bioprinting

Humidity poses a nightmare for any place with rigid controls. In terms of Bioprinting, a humid environment can result in water to settle on surfaces, including your printers and the bioink. Dirt can collect and the moisture provides an ideal breeding ground for bacteria, compromising the sterility of the environment.

Soft polymers such as hydrogels are also widely used in tissue and organ fabrication because they have grate biocompatibility and a tunable mechanical strength. They are highly absorbent, temperature-responsive materials that also happen to absorb water molecules from the air. To stop the material from absorbing moisture and compromising its integrity, the humidity of the surrounding environment needs to be tightly managed.

What’s the solution?

The right solution needs to control humidity, as an uncontrolled humid environment can affect cell growth and proliferation. In fact, research shows that the cells are most likely to survive when humidity is maintained at 65-85% RH.

A bespoke desiccant dehumidifier is one of the best solutions as it not only removes moisture from the air but also allows you to have complete control of your environment from a control panel. Essentially, you can create and maintain the conditions you need for Bioprinting.

Conclusion

Ultimately, controlling the humidity of your bioprinting environment isn’t a choice; it’s essential, which means you have to make the right choice for your dehumidifying solution. For such strict environmental controls, a desiccant dehumidifier effectively and efficiently meets the requirements to maintain the integrity of your environment.

For over twenty-one years, Dehum (Sorption Wheel Services Limited) has been a major supplier of humidity control systems. We are a true Engineering Company, designing, supplying and coordinating installations of equipment alongside complimentary services. Our global client list spans across all industries, including food & drink, pharmaceutical, nuclear, automotive, aviation, chemical processing, ice prevention/cold storage, car storage and archives.