Electronics Humidity Control

Manufacturing electronics requires exact conditions to be successful. If you’re unable to control these conditions, large batches of products can be ruined in an instant, greatly affecting your bottom line.

One of the most important factors to monitor is humidity. Too much or too little can have a serious effect. Thankfully, we have a solution.

The Importance of Humidity Control in Electronics Production

So why is controlling humidity so important? Usually you reduce the humidity within your application to prevent excess moisture from forming, which can lead to mould or rust in your factory, warehouse, or other industrial areas.

However, when producing electronics, controlling humidity is still incredibly important, but not for the same reason. It’s true that excess moisture can cause the same issues as in other applications, but here it can do much more damage. And unlike in other industries, too little humidity can also ruin your output.

The Danger of ESDs During Device Production

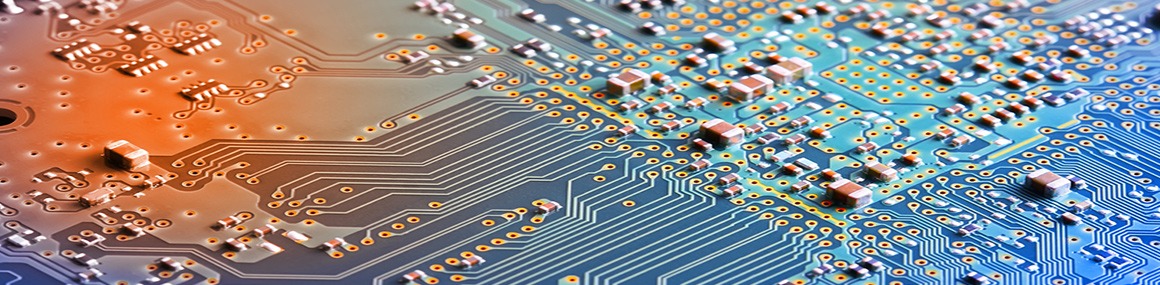

Electrostatic Discharge (ESD) is a common issue when producing electronics such as circuit boards, components, resistors, and transistors. An ESD occurs when two differently charged objects come into contact with one another, and a spark is created.

This spark is rarely strong enough to cause physical harm to someone handling the devices, but it is enough to damage the components themselves. It can be visible/audible but can also be hard to miss on a production line. An ESD can cause a device to fail, or it can affect the long-term reliability of the final product.

As you can imagine, either of these issues can harm your reputation, and can even lead to legal trouble if your devices don’t achieve the lifespan you promise. In tech, one of the most competitive industries in the world, reputation is everything, and shipping a ‘bad batch’ of electronics can do lasting damage to your business. This is ignoring the potential dangers of ESDs, which can be harmful if the spark is large enough.

Preventing ESD with Humidity Control

ESDs are usually a result of static electricity. We can pick up small static charges from clothing, carpets, and similar materials. This is usually not an issue, but if you’re statically charged and then handle electronics, ESDs can occur. It isn’t the only cause of ESDs but is the most common when manufacturing electronics.

So what’s the solution?

Well, if you’re a regular visitor to our site, you’ll know that we specialise in reducing humidity in a wide variety of applications. However, when it comes to preventing ESDs, more humidity is the best solution.

A relative humidity (RH) of around 40% all but eliminates the chance of ESDs, as the moisture in the air acts as a natural conductor for the charges, a barrier between each device that prevents the spark from jumping from one to the other.

However, this window isn’t easy to achieve without the correct system in place. Too much humidity can affect the performance of your devices and can cause irreparable damage to some of the more sensitive components you work with.

Our advanced humidity control systems help you achieve the perfect RH window so that you never have to worry about the conditions within your application. Standard industrial dehumidifiers may be able to reduce the humidity but can’t keep it at the optimal levels the same way our bespoke dehumidifier systems do. If conditions need to be perfect, we have the perfect solution for your business.

The Best Humidity Control Systems for Cleanrooms

Most electronic devices are manufactured in cleanrooms. These are separate rooms within your application that are controlled environments, meaning the ambient temperature and RH are closely monitored and adjusted to suit the job at hand. They’re also kept free from dust and other harmful particles that can damage sensitive equipment and devices.

Without humidity control it’s impossible to achieve these optimal conditions, and you might as well not be using a cleanroom at all.

At Dehum we specialise in problem solving and optimisation. Companies either approach us with a humidity-related issue or simply want to improve their productivity and product quality. If they’re not getting the optimal conditions within their cleanrooms, we jump into action and find out why via a thorough inspection. Once this assessment is complete, we design a bespoke desiccant rotor system that’s perfect for their business. We work with the space and facilities you have, so there is minimal impact on your business and as little downtime as possible while it’s being installed.

Whatever your requirements, we will work with you to create a solution that optimises your application and guarantees you’ll see an increase in yield and profit margins straight away.