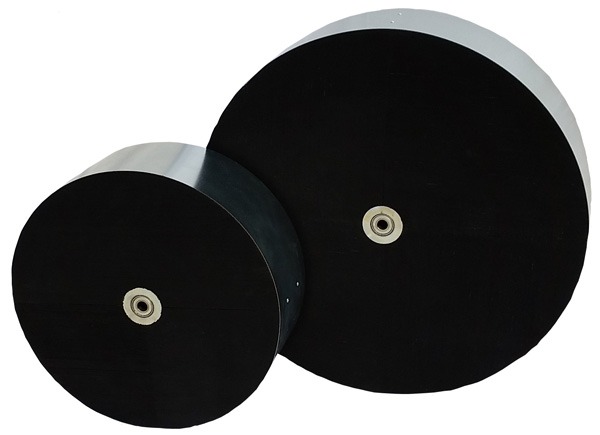

Desiccant Rotors

What Are Desiccant Rotors?

The desiccant rotors are used in all of our equipment and is at the heart of every dehumidifier unit. The ‘engine’ if you like. The desiccant wheel is the most critical component that allows the dehumidifier unit to remove the moisture to the levels required by the process it has been designed to serve.

How Do desiccant Rotors Work?

Constructed from a finely fluted structure, the desiccant drying rotor provides an enormous surface area for the airflow through the unit. This structure is impregnated with a desiccant salt – usually silica gel – which absorbs the moisture from the air and delivers it onwards to the process or diverts for further processing.

Our desiccant wheel represents the current state of the art in specific moisture removal per kW of energy input to the machine, allowing for the most efficient moisture removal available to the industry. It is proven (in independent tests) to offer 8.5% more specific dehumidifying performance and 25% less pressure drop through the structure.

Specifications of desiccant rotors?

- In our standard range of machines, our drying rotors range from 220mm to 1940mm in diameter, handling between 100 and 25,000m3/hr of air.

- For larger applications, desiccant wheels are available in diameters up to 4500mm, capable of handling over 100,000m3/hr of process air.

- Available in various depths, from 50mm to 400mm, to meet all requirements. And careful design optimises the selection of material.

- To meet specific requirements, it can be manufactured with a combination/variety of absorbents, including silica gel. For example, low dew point drying for the production of lithium batteries often requires what are known as ‘combination’ desiccant rotors, where a molecular sieve may be necessary.

Advantages & Benefits Of Desiccant Rotors?

- All our desiccant rotors are manufactured to exacting standards and available in all sizes to suit any application and manufacturer’s product range.

- The structure and construction of the rotor material have been rigorously tested under all relevant standards and found to be safe for use in any process and environment.

- The material is non-flammable, does not support flame spread, and is non-toxic.

- It will not shed any particles under everyday use

- They are used across various applications, including in the food and pharmaceutical industries, where cleanliness is paramount.

Why DEHUM Recommends Desiccant

There are several ways to control humidity within a business, the most common of which are ventilation, heating and cooling. However, these all come with significant drawbacks, specifically:

- Ventilation – To be effective, ventilated air has to have a lower moisture content. Thus, it is at the mercy of changing weather conditions.

- Heating – Heating lowers relative humidity (RH%), but absolute humidity and dew point remain unchanged. Heating also demands high levels of energy.

- Cooling – Compressor dehumidifiers utilise cooling to reduce the absolute humidity by removing moisture on a cold coil. This increases the RH% to 100% before a re-heat coil in the exact mechanism reduces the relative humidity. This method lacks efficiency in ambient temperatures below 10°c and creates free water, which can result in health concerns. This method also requires more maintenance than desiccant dehumidification solutions and contains HCFCs, which are harmful to the climate.

At DEHUM, We Focus on Desiccant Dehumidifiers to:

- Reduce RH% levels

- Reduce absolute humidity

- Reduce dew point

- Use lower air volumes, resulting in less energy used and less noise created

- Extend equipment life

- Provide options for energy use (electricity, steam or gas)

- Operate at temperatures between -40°c and +40°c

How Does a Desiccant Dehumidifier Work?

Put simply; a desiccant dehumidifier utilises a fan which draws air into the dehumidifier. The moist air is passed through the rotor (described above), which slowly rotates, absorbing water vapour from the air into a silica gel salt. The warm, dry air is then fed back into the room free of humidity.

The silica gel is moved into the regeneration section, where a small volume of air is heated to remove the moisture from the gel, where it is then passed out of the building. This process is continuous and ensures that desiccant dehumidifiers require no emptying of trays and less maintenance than competing dehumidification technologies.

Advantages of Desiccant Dehumidifiers:

- Desiccant dehumidifiers operate independently of temperature, continuing to work effectively at well below 0°c.

- Desiccant dehumidifiers contain no HCFCs, which are harmful to the environment.

- The lifespan of a desiccant dehumidifier is often significantly longer than a refrigeration dehumidifier, owing to the reduced number of moving parts.

- Although specific power ratings for desiccant dehumidifiers may appear higher than a comparable refrigeration unit, they run for shorter periods to remove similar amounts of water. This ensures that desiccant dehumidifiers use less energy than their refrigerant counterparts.

- Where RH% levels below 40% are required, desiccant dehumidifiers are the only reliable option. They can achieve RH% levels of less than 1%.