How to Gain a Competitive Advantage in 3-D Printing Manufacturing Using Humidity Control

February 19, 2020

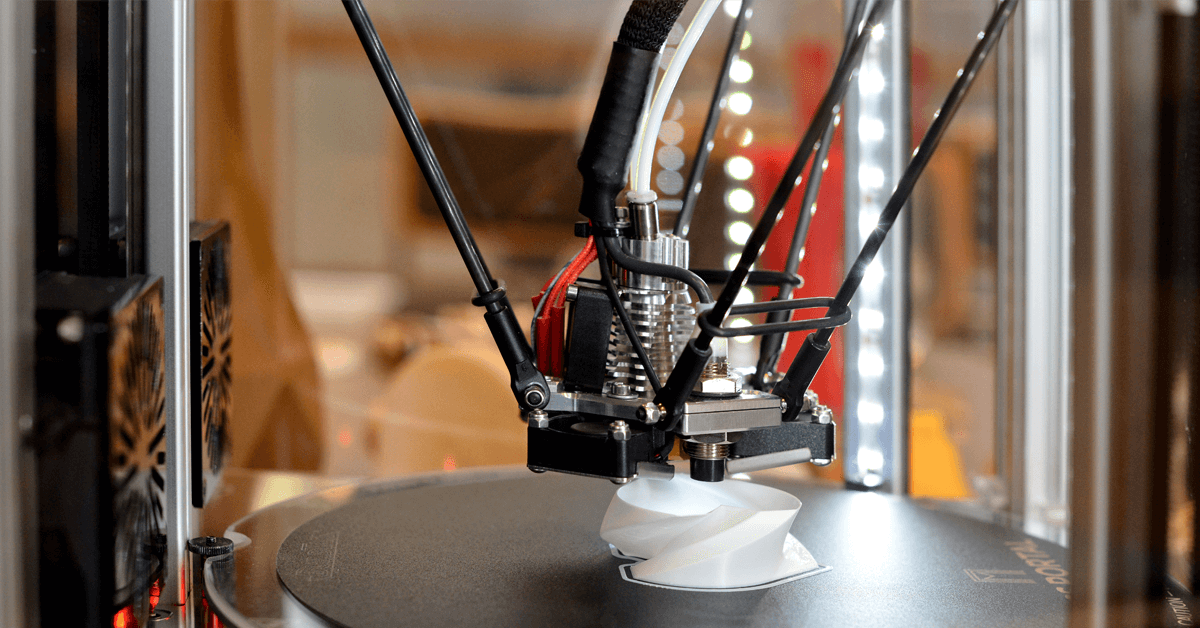

3-D printing is one of the most important industries that will be at the forefront of the manufacturing world for the foreseeable future.

The ability to produce high-quality products rapidly has transformed 3-D printing from a novel idea into an industry juggernaut that remains in its formative years, despite it having been around for decades.

3-D printing has undergone a rapid expansion, and a general improvement has directly influenced in technology across the board.

No longer used exclusively by the engineering world to test ideas, 3-D printing has become something that has end-uses in every industry, from architecture to fashion, aviation to healthcare and beyond.

With something that has such a wide scope of applications, versatility in design and accuracy in printing, maximising that potential is the logical step for anyone who is helping to innovate and revolutionise the world of design, regardless of the industry.

On a micro-scale, 3-D printing is an ideal way to test ideas designed and viewed in CAD to see how they function outside of the virtual world. The next step is to intensify the scale of production; Xerox CTO Naresh Shanker has commented on this:

“For broad adoption of 3D printing on the factory floor, two things need to happen. First, there will be an increased focus on advancing the infrastructure required to support 3D printing — and by infrastructure, I mean everything beyond the printer that makes additive manufacturing happen: additive design, manufacturing workflow, and new or improved materials.”

There are two fundamental areas for improvement in 3-D printing: quality and scale.

So, where do we start?

Product quality affects everyone, from a small 3-D printing house to a larger facility. With a greater quality in materials, workflow and accuracy, it will be much easier to scale up the process.

From hobbyists to industry leaders- sorting filament will be the first port of call.

Different types of filament will all have slightly different reactions to the atmosphere that they are stored in. For the hobbyist- there are plenty of suggestions on how to combat this, but for anybody outside of that world, a much more robust solution is required.

It is recommended that around 10-13%RH (relative humidity) should be maintained whilst storing most types of filament. Though there may be slight variances between types (especially the extremely hygroscopic nylon) – the basic idea is the dryer, the better.

The correct storing of filament is vital to ensuring product quality. If moisture is absorbed into the filament before a design is printed, then the entire process can be ruined before it’s even started.

On the other side of the spectrum is the developing idea of bioprinting within the health industry.

For a whole host of different reasons, it is even more important to maintain the perfect conditions for materials within that process. The stakes are far greater for a world that is working on perfecting artificial organs compared to visualising engineering solutions.

Why is quality so important?

3-D printing is commonly known for being a precise means of testing the design of components before the design is finalised and formed into a mould for an injection moulding process. So for many, reliability and overall quality of materials aren’t seen as ‘must-haves’.

The face of 3-D printing is changing, and improving quality is the only way to be at the forefront of that change and innovation.

Technology has taken us to the point where hobbyists have the opportunity to design and create interesting designs. This means that there needs to be a large step up in quality between the hobbyist and the industry leaders to make products that are worth spending money on as opposed to the DIY approach.

The other aspect to why quality is so important now is seen in the end-use of 3-D printed products.

With an equal amount of focus on creating final products instead of just tests, the consistency, strength and longevity of 3-D printed products must be improved. This, again, all comes through improving storage conditions and removing moisture from them.

Improving the quality of the 3-D printing process is so important because it will help to drive the industry forward rather than stagnate. Maximising the potential of every process step will allow this world to take a step up truly.

This begs one question…

How do we do it?

To gain total control over the conditions in your 3-D printing facility- whether a small shop or a large factory, desiccant dehumidification is your solution.

From industrial applications to those within health care, reducing the moisture levels will give you total control over your room conditions, meaning you have total control over your process.

Maintaining an ideal environment for all the materials that are used within the 3-D printing process has a whole host of advantages. Filament will never spoil, equipment will never rust, and all downtime will be heavily reduced.

Especially in a climate such as that of the UK, controlling ambient conditions within any process is an important consideration. Our average relative humidity level throughout the year sits at the 80% mark. This means that every hygroscopic material used within the 3-D printing process, namely the filament, is at constant risk of losing molecular integrity.

Conclusion

By eliminating the effects of humidity on your workflow at its source, a bespoke desiccant dehumidification system can revitalise the world of 3-D printing.

The industry has set lofty goals of industrial-grade expansion with a huge upturn in quality. The only way to make this a reality is to maximise the potential of the processes developed so far.

Dehumidification allows your existing workflow to improve and takes you to the next step of perfecting your 3-D printing.

For more information on how Dehum can help with 3-D printing, please visit http://dehum.com/applications/general-industrial/ or call us on 01926 882624.

For over twenty-one years, Dehum (Sorption Wheel Services Limited) has been a major supplier of humidity control systems. We are a true Engineering Company, designing, supplying and coordinating equipment installations alongside complimentary services. Our global client list spans all industries, including food & drink, pharmaceutical, nuclear, automotive, aviation, chemical processing, ice prevention/cold storage, car storage and archives.